Closed-loop recycling saves critical natural resources. More than 92% of recycled aluminum can material is made back into a new aluminum can.

COMPLETE RECYCLING PROCESSES

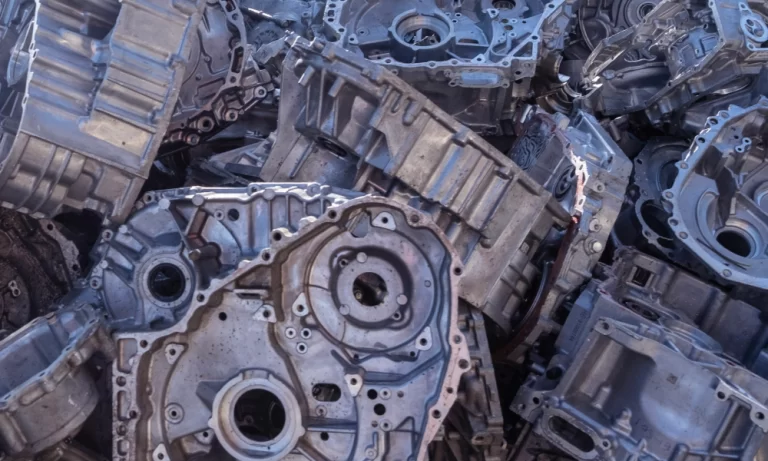

The closed-loop recycling of aluminum was commonplace well before the idea of recycling became widespread. Using recycled aluminum requires a fraction of the energy that would be otherwise used for primary production. The infinite reusability of aluminum makes it the logical choice for environmentally conscious customers seeking greater efficiency in their metal supply.

At REAL ALLOY, we have developed state-of-the-art aluminum recycling processes to deliver even better results to our clients. With a combination of cutting-edge technologies and flexible delivery solutions, we are able to provide maximum value to our customers. With our processes, we efficiently convert scrap metals into usable products and goods. Contact us to learn more about our recycling operations.

Full Array of Customer Solutions

RECYCLING

Our recycling operations offer comprehensive recycling solutions by converting purchased or customer owned scrap into a reusable form.

SPECIALTY PRODUCTS

Our specialty products operations focus on materials that cannot be directly recycled in a furnace and instead require mechanical processing.

SPECIFICATION

Our specification alloy operations combine various aluminum scrap types with hardener’s and other additives, in order to produce alloys in accordance with our customers requirements.

SPECIALTY METALWORKS AND ALLOYS

In addition to providing recycling solutions, our company also specializes in other metalworking processes. This includes creating specialty products that cannot be directly recycled in a furnace, instead requiring mechanical processing. We can also produce specific alloys by combining aluminum scrap with various hardeners and other additives to create alloys that fit your business needs.

DEDICATED TO QUALITY RECYCLING SERVICES

As a recycler of aluminum scrap, our business model revolves around resource efficiency, environmental protection, and energy management. The focus of our operations is reclaiming valuable metal from waste and returning it back into the cycle of valuable products. Careful scrap management and separation, sophisticated blending calculations, advanced production technology, and strict quality control allow us to achieve maximum recoveries of high-quality recycled light metal alloys with the least possible demand on energy and other resources. The environmental impact of our business activities is regularly and comprehensively monitored and documented through internal programs. Contact us to learn more about our commitment to excellence or to discuss our company’s values on sustainability and environmental improvement.